L605 Sheet, Plate, & Bar

(AMS 5537, AMS 5759, UNS R30605)

Alloy L605, also called HAYNES® 25 and Cobalt L-605, is a solid solution, cobalt-nickel-chromium-tungsten alloy that is useful for continuous service to 1800°F (980°C). L605 is the strongest of the fabricable cobalt alloys and has been the subject of many investigations to determine its properties over a wide of conditions because of its long and widespread use. Alloy L605 exhibits a loss of room temperature ductility in much the same way as other superalloys, such as alloy X or alloy 625, when exposed for prolonged temperatures at intermediate temperatures. L605 from Altemp is specified to AMS 5537 & 5759.

L605 Features

- Excellent resistance to sulfidation

- High-temperature strength

- Resistance to wear and galling

- Great ductility, forming, & welding characteristics

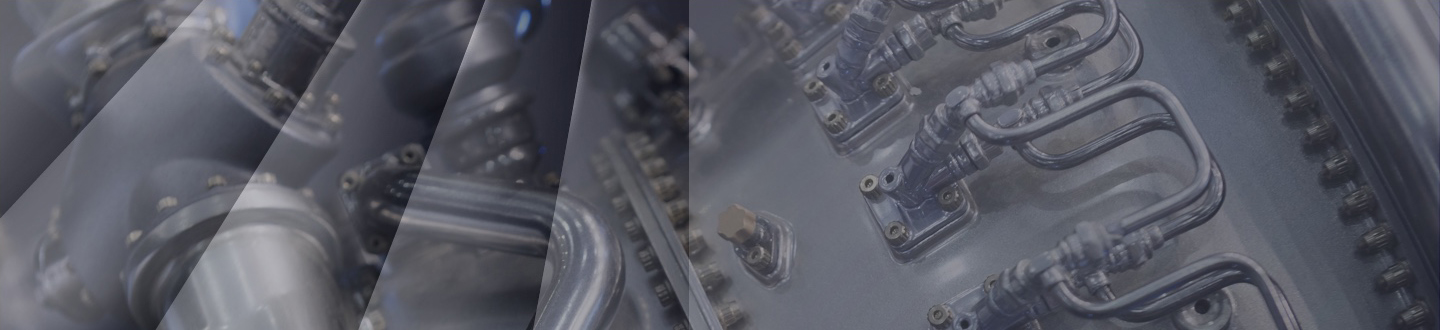

Alloy L605 Aerospace Applications

L605 has given g nine components such as combustion chambers and afterburners. Other aerospace applications include:

- Turbine blades & rings

- High-temperature ball bearings and bearing races

- Springs

- Heart valves

L605 Welding

Haynes 25 can be welded in the following methods:

- Shielded metal-arc

- Gas tungsten-arc (TIG)

- Gas metal-arc (MIG) methods