Inconel 625 Sheet

(AMS 5599, ASTM-B-443, ASME-SB-443, UNS N06625)

Inconel® 625 sheets exhibit superior strength and durability and are prized for their outstanding oxidation and corrosion resistance. Maintaining their integrity across a temperature range spanning from cryogenic deep-freezes to 1000 degrees Celsius/2000 degrees Fahrenheit, Inconel® 625 sheets, commonly referred to as Nickel Alloy 625, are nickel-based, using columbium and molybdenum as refractory metals. During testing in hostile corrosive conditions, Inconel® 625 displayed near-impenetrable resistance to salt water, neutral salts, fresh water, air and alkaline chemicals.

Altemp Alloys stocks Inconel® 625 sheet (UNS N06625) to the following specifications:

| Specifications | |

|---|---|

| AMS 5599AMS 5879ASME SB-443 Gr. 1ASTM B-443 Gr. 1UNS: N06625W. NR.: 2.4856ASTM: B 446 GR 1ASME: SB 443 GR 1AMS: 5666 5837NACE: MR0175ISO: 15156SAE AMS5599SAE: AMS5599 AMS 5666UNS: N06625W. NR.: 2.4856ASTM: B 446 GR 1ASME: SB 443 GR 1NACE: MR0175 MR0103ISO: 15156 17945GE: S-400/S-SPEC-35 S-1000/S-SPEC-1RR: SABRE AEROSPACEASTM 443 | Quote |

Inconel 625 Sheet Industries

Thanks to Inconel 625 Sheet's pressure, heat, and corrosion resistance, Inconel® 625 is frequently used in a variety of industries, including:

- Chemical processing

- Marine engineering

- Power generation

- Aerospace engineering

- Hardware manufacturing and engineering

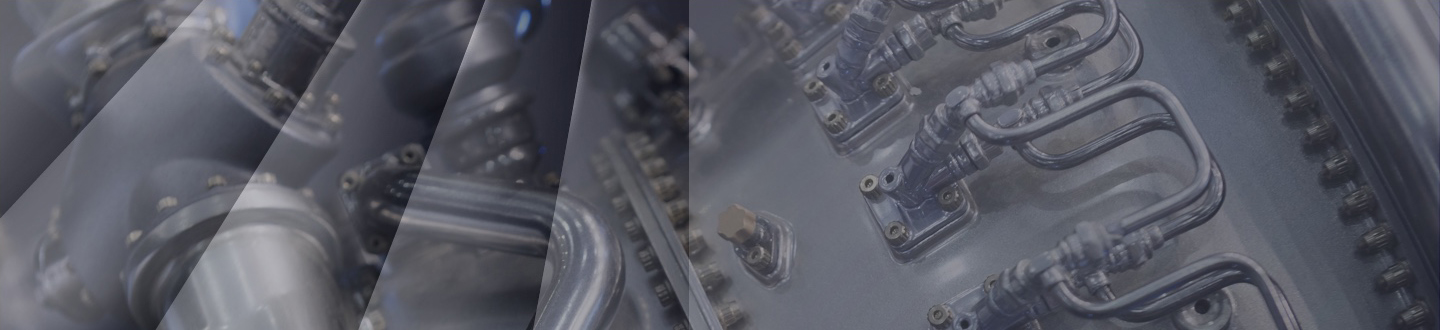

Inconel 625 Sheet Applications

Specific applications of Inconel® 625 sheets include:

- Furnace hardware

- Ductwork for gas-powered turbine systems

- Acid storage and production equipment

- Production tubing for sour gas

- Heat shields

- Chimney liners

- Heat exchangers

- Distillation columns

- Bubble caps

Inconel 625 Sheet Attributes

Inconel® 625 also exhibits strong stability during welding, thanks to the presence of niobium. This super-alloy is also valued for its high levels of fatigue strength and imperviousness to chloride ions. Pickling is achieved by treating the super-alloy with sodium hydride, then submerging it in sulfuric acid for three minutes at a temperature of 74 degrees Celsius/165 degrees Fahrenheit.

Inconel® 625 super alloys are also available in plate, bar, forgings and tubing. Contact Altemp Alloys today for your Alloy 625 sheet needs!