Inconel 718 (UNS N07718)

Altemp Alloys is a supplier of Inconel® Alloy 718 (UNS N07718), a nickel base superalloy frequently used for cryogenic storage tanks, turbines, down hole shafting and well head parts. High tolerance to extremely high and low temperatures allow Inconel 718 to be welded and annealed into products that will withstand extreme conditions. Other uses include jet rocket, nuclear fuel, and pump body components. Inconel® 718 from Altemp is specified to AMS 5596, 5597, 5662, 5663, 5664 & ASTM B-637

Altemp Alloys offers Inconel® 718 in:

Sheet (AMS 5596, ASTM-B-670, B50TF14 Class A&E, UNS N07718)

Plate (AMS 5596, ASTM-B-670, B50TF14 Class A&E, UNS N07718)

Round Bar (AMS 5662 Solution Heat Treated, Capable of AMS 5663, UT per AMS-STD-2154 Type 1 Class A, ASTM-E-2375 Type 1 Class A, UNS N07718)

Round Bar (Precipitation Heat Treated and Aged AMS 5663, B50TF15 Class B&E, ASTM-B-637, ASME-SB-637, UNS N07718)

Flat Bar (AMS 5662 Solution Heat Treated, Capable of AMS 5663, UT per AMS-STD-2154 Type 1 Class A, ASTM-E-2375 Type 1 Class A, UNS N07718)

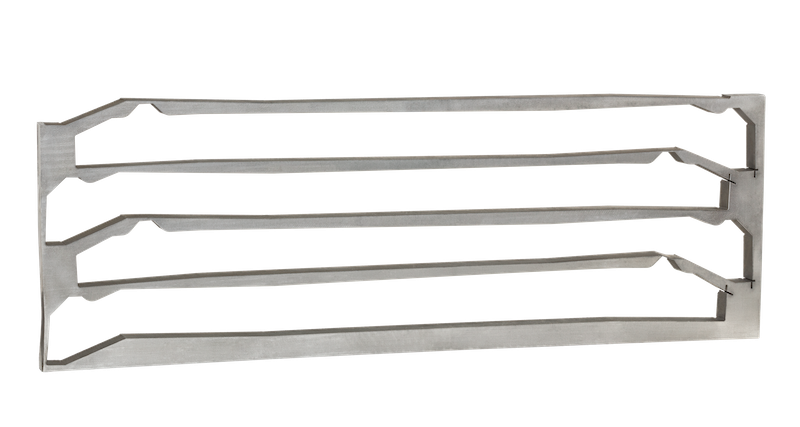

Forgings (AMS 5664, B50TF15 Class B&E, ASTM-B-637, ASME-SB-637, UNS N07718)

Specifications

Altemp Alloys offers Alloy 718 (also known as UNS N07718) in:

| Shape | Specifications | |

|---|---|---|

| Sheet | AMS 5596AMS 5597GE B50TF14ASTM B-670 | Quote |

| Plate | AMS 5596AMS 5597GE B50TF14ASTM B-670 | Quote |

| Bar | AMS 5662AMS 5663AMS 5664GE B50TF15 Class B & EASTM B-637ASME-SB-637UNS N07718 | Quote |

| Forgings | AMS 5662AMS 5663 AMS 5664GE B50TF15ASTM B-637 | Quote |

Chemical Composition

Inconel® 718 is made up primarily of nickel (52%). Alloying elements include Iron (19%), Chromium (18%), Columbium+ Tantalum (5%), Molybdenum (3%), Titanium (0.9%), Aluminum (0.5%) with the addition of other elements in trace amounts such as Baron, Cobalt, Copper, Manganese and Silicon.

Inconel® 718 Physical Properties

Inconel® 718 features a melting point of 2300°c and possesses impressive tensile strength that lends itself well to the wide variety of industrial applications it is involved in such as fasteners, high-strength bolts and nuclear fuel element spacers to name but a few. This is further aided by the alloy's excellent performance in properties such as weldability and creep-rupture.

Our Range of Inconel® Alloys

Altemp Alloys also carries a number of other Inconel alloys, including: