17-7 PH Stainless Steel (UNS S17700)

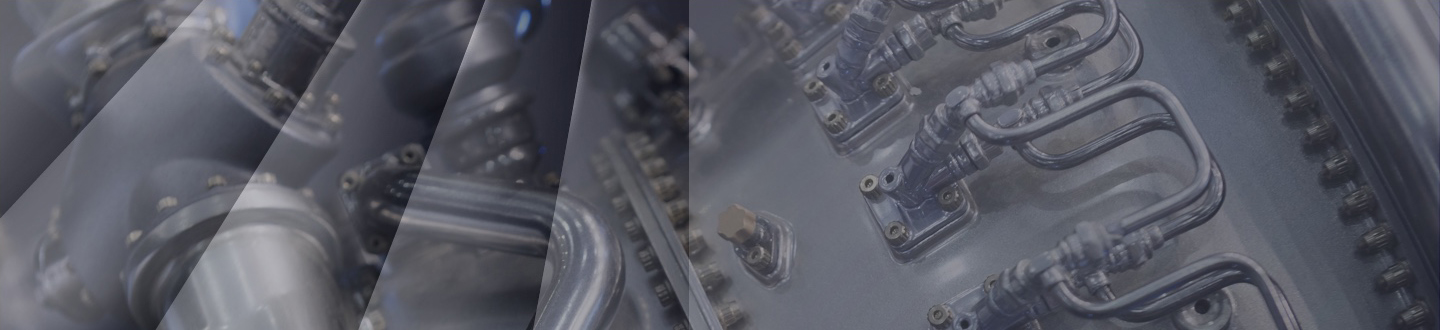

Altemp Alloys carries a variety of stainless steels with the ability to withstand high temperatures. Of the most frequently used in the the aerospace industry and when meticulous, elaborate parts are needed, 17-7 PH stainless steel is a common choice.

Altemp Alloys carries a variety of stainless steels with the ability to withstand high temperatures. Of the most frequently used in the the aerospace industry and when meticulous, elaborate parts are needed, 17-7 PH stainless steel is a common choice.

A stable, chromium-nickel-aluminum steel, 17-7 is a precipitation hardening steel with a high strength and moderately resistant to corrosion. In terms of corrosion resistance, 17-7 PH stainless steel is comparable to 304 stainless steel and a better choice when compared to the 400 series of stainless steel. 17-7 from Altemp is specified to AMS 5528, 5529, 5644 & ASTM A 564, 693.

17-7 PH Shapes

Altemp Alloys offers 17-7 PH stainless steel UNS S17700 in:

17-7 PH Composition

The chemical composition of 17-7 breaks down as follows:

- Chromium: between 16.0 and 18.0 percent

- Nickel: between 6.50 and 7.75 percent

- Aluminum: between 0.75 and 1.50 percent

- Manganese: up to 1.00 percent

- Silicon: up to 1.00 percent

- Carbon: up to 0.09 percent

- Phosphorus: up to 0.04 percent

- Sulfur: up to 0.03 percent

- Iron: makes up the remainder

Standard 17-7 PH Heat Treatments

Heat treatments can strengthen this type of stainless steel. The approved process for 17-7 PH heat treatments has three steps:

- Conditioning using austenite.

- Cooling, which turns the austenite into martensite.

- Precipitation hardening until Condition TH 1050 or RH 950 is reached.